Biomass Bioenergy

Academic articles06 de March de 2026

Types of bioenergy sources from biomass

Biomass is the total mass of organic substances that occur in a habitat. There are various types of biomass on the planet, which can be used in different ways. Examples of biomass uses are in the food industry, in the manufacturing process of various products, or in construction.

Biomass is the total mass of organic substances that occur in a habitat. There are various types of biomass on the planet, which can be used in different ways. Examples of biomass uses are in the food industry, in the manufacturing process of various products, or in construction.

When its original use ends, biomass can be used secondarily for energy generation. For example, organic waste, which is a mixture of discarded material, can be used as a source of renewable energy.

The energy contained in organic waste is usually used through biogas generation. In landfills, part of the organic waste is converted into methane, which is usually wasted. In some cases, however, direct fermentation of these residues in anaerobic treatment systems can be advantageous. Residues with a high wood content can also be dried and burned as solid fuel.

An area of study of biomass applications involves the creation of crops for energy purposes, planted to be used directly as fuel. This issue will be discussed in the following sections, analyzing the various types of biomass sources.

Biomass sources

Biomass can be classified into four categories, according to its origin:

Biomass can be classified into four categories, according to its origin:

Crops for energy generation: are cultivated for energy production. Their function is to capture solar radiation to store it in biomass. Examples of energy crops are rapeseed, sunflower, and corn.

Agricultural and forestry residues: These are residues that are naturally generated in the harvesting of cereals and tree cutting, such as straw and wood residues. This group of "by-products" is especially suitable for recycling for energy generation because it reduces the production costs of main products or increases the yield of the cultivation chain.

Organic by-products: The processing of biomass to create products forms an additional group of by-products. These by-products include organic waste, agricultural effluents, and residues from the industrial processing of wood and plant fibers. In these cases, recycling for energy generation can lead to increased utility and ensure that parts of the production process are permanently and environmentally sustainable.

Organic waste: Examples include household waste, domestic and industrial effluent sludges, and food production waste. These residues are generally subject to respective legislation. Consequently, legal requirements must be met, from the origin to the epidemic control of residues.

Plant biomass is generally in a solid state. It has a geometric shape and a water content that, in most cases and for technical reasons, directly interferes with its use for energy generation.

Biomass sources used as fuels are classified according to the aggregation state in which they are found: solid, liquid, or gaseous.

The existing aggregation state determines the possibilities of using biomass sources and the type of energy generation infrastructure required. Heat exchangers or combustion systems that combine heat and power are capable of using solid fuels, while combustion engines are not.

The form and aggregation state of processed biomass products are determined by available conversion technologies and systems.

In the process of converting biomass into energy, there are optimized operating methods for each type of use, biomass characteristics, and specific performance levels.

To achieve efficient operation, these levels and characteristics must be kept within strict limits.

Use of biomass sources

There are three fundamental forms of energy: heat energy, mechanical energy, and electrical energy, and all of them can be obtained from biomass sources.

There are three fundamental forms of energy: heat energy, mechanical energy, and electrical energy, and all of them can be obtained from biomass sources.

There are many possibilities for generating the desired forms of energy from biomass sources, in different aggregation states.

Heat Energy

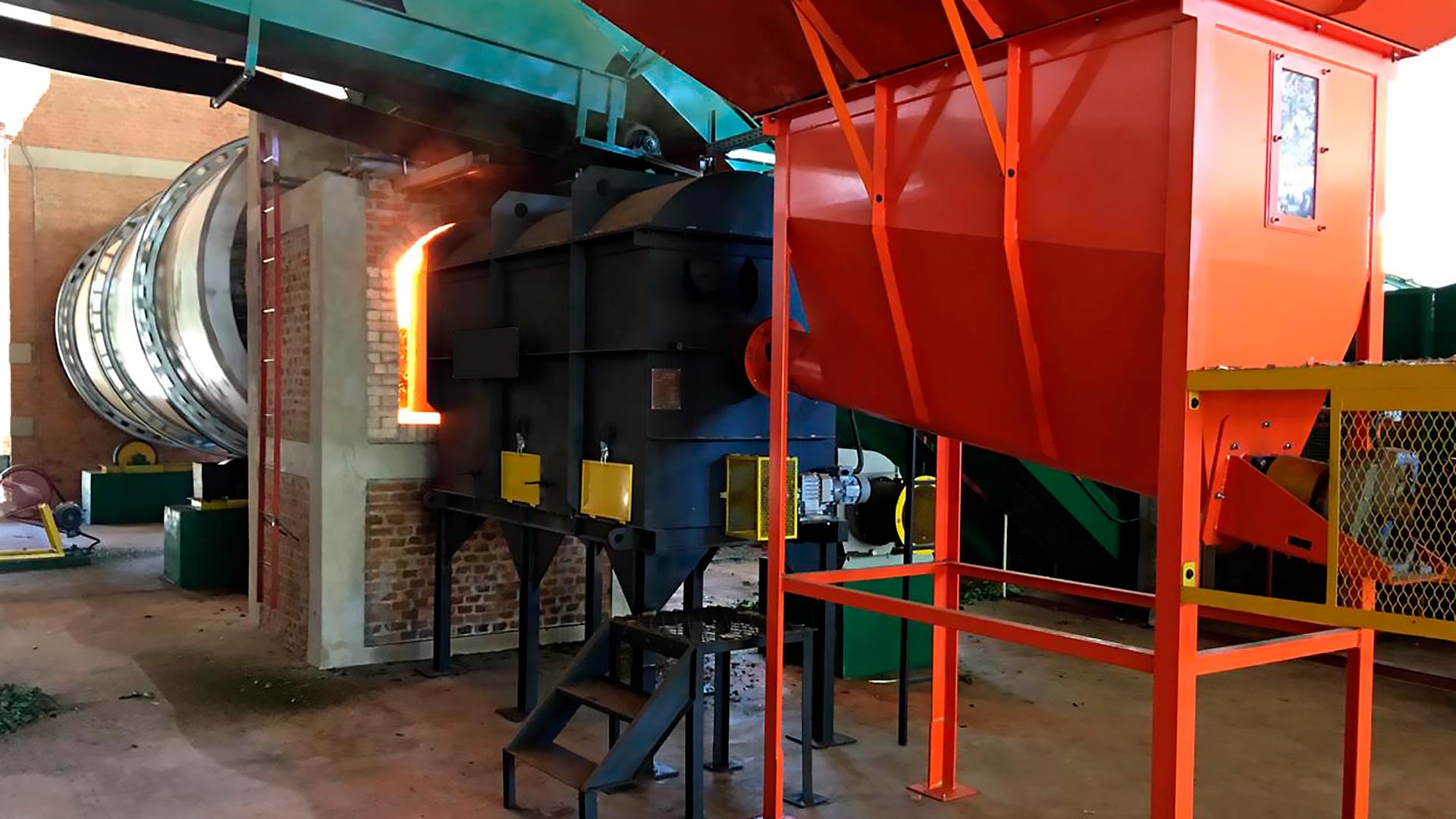

Heat is typically produced in combustion systems. On a small scale, these systems can heat a dwelling, while on a large scale, the heat generated in a plant and through distribution networks can heat homes in several city blocks.

For stationary combustion systems, whose sole function is heat production, solid fuels predominate in terms of biomass. Wood, as waste or raw material, can be used for heat generation, with low processing costs, shredding, or drying.

Mechanical Energy

Mechanical energy is produced through heat and power generators, such as combustion engines. In these, the liquid or gaseous fuel is ignited in the cylinders, and the expansion of the fuel/air mixture, caused by combustion, is then converted into energy. The heat produced by this process must be dissipated to the environment through a cooling system.

The use of biodiesel in Europe, for example, a blend of ethanol in France and the use of pure ethanol in Brazil, are examples of successful use of biomass sources in the transport sector.

With vegetable oils extracted from sunflower seeds and other oilseeds and alcohol produced from biomass, it is possible to meet the fuel needs for transportation. Biomass fuels are a viable alternative, equivalent to fossil energy sources.

Electrical Energy

Systems that produce mechanical energy like combustion engines or direct and indirect combustion turbines are coupled to electric generators, which convert mechanical energy into electrical energy.

Using mechanical energy to produce electrical energy generates approximately two-thirds of heat for one-third of electricity, demonstrating the increased economic efficiency of cogeneration (simultaneous production of heat and electricity) in stationary applications.

Biogas, derived from landfills, recycling of agricultural residues, or other organic waste, can be used in stationary plants for energy production.

Solid biomass sources

The largest source of solid biomass residues comes from wood processing. Residues are obtained when wood is removed from forests and in the industrial processing of wood products. In many places, other biomass sources such as straw are also used to produce energy.

The largest source of solid biomass residues comes from wood processing. Residues are obtained when wood is removed from forests and in the industrial processing of wood products. In many places, other biomass sources such as straw are also used to produce energy.

In forest thinning, in addition to the tree trunks used for furniture and construction industries, lower quality wood residues are also collected. From these residues, 0.4 - 0.8 tons of dry firewood can be obtained per hectare of forest. In addition, other forest maintenance actions generate annual wood residues of about 1.5 tons per hectare, for a forest area of permanent use.

In forest operations, trees are felled with the aid of machines, which use an arm with an attached saw. Additionally, these machines can automatically remove branches from the trunk, peel off the bark, and cut the trunk into pieces. This method allows part of the wood processing to be done before the wood leaves the forest.

When round logs are transformed into planks and beams, large amounts of waste are produced. However, most of these are used in the wood industry for other purposes. Wood chips without bark, for example, are raw material for the production of high-quality charcoal.

However, another part of these residues still contains impurities and is therefore unsuitable for use as raw material. These bark pieces are ideal for recycling for energy generation. Due to the high ash content, these residues are mainly used in large heat supply plants and cogeneration plants as co-combustion substrate.

Other significant residues from agriculture include straw and hay. Post-harvest residues are usually available locally and in large quantities.